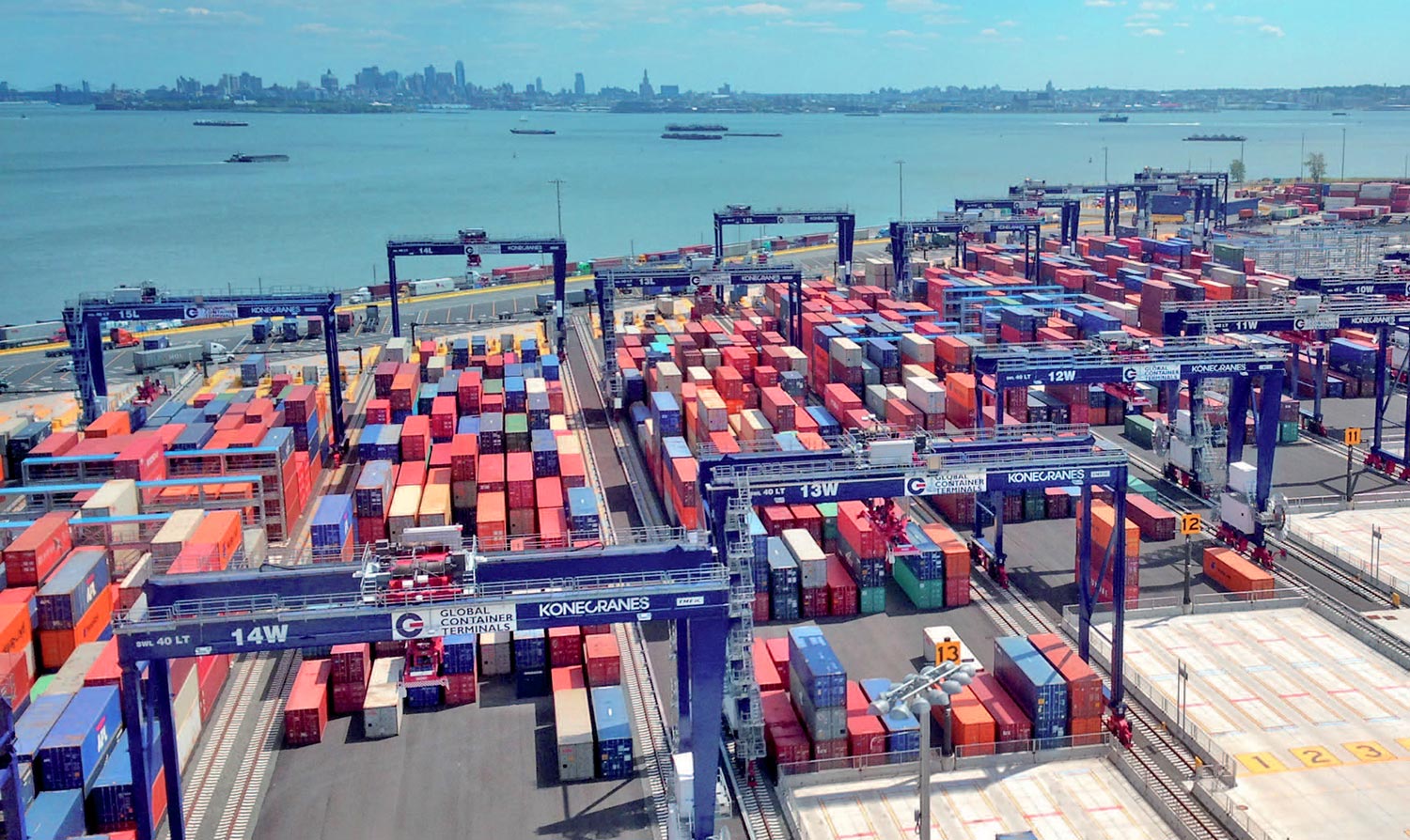

The problem of container stacking is common in the operation management of port terminal yards, which is to meet the constraints such as delivery time limit, weight limit and stacking height restriction under the premise that the number of containers is known, and the goal is to achieve the minimum number of occupied pallets.

In container terminals or freight yards, containers need to be stacked vertically. It is a complex logistical issue that involves considerations such as stacking height, stacking stability, space efficiency, and operational automation.

In container yard palletizing, common operations include manual and mechanical palletizing. Manual palletizing typically requires operators to use tools such as stacker cranes or forklifts to move containers from the ground or other palletizing locations to a target location for palletizing. Mechanical stacking is carried out with the help of equipment such as stacker cranes, automated guided vehicles or automated systems.

Common difficulties and challenges in container yard stacking include:

1. Stacking height: Container yards usually need to stack containers vertically to a higher height to make full use of the yard space. The height of the stacking has certain limitations, and it is necessary to consider the bearing capacity of the equipment, the stability and safety factors of the stacking.

2. Stacking stability: During the stacking process, it is necessary to ensure the stability of the container to prevent accidents caused by collapse and tilting. Especially in stacking with higher heights, the requirements for stacking stability are higher, and some measures need to be taken, such as using fixed fixtures or supports, reasonably adjusting the position of the container, etc.

3. Space efficiency: Container yards often have limited space and need to stack as many containers as possible in a limited space. Therefore, it is necessary to reasonably plan the stacking method of containers, make full use of the yard space, and avoid space waste.

4. Degree of automation: With the development of logistics automation technology, container stacking has also begun to improve operational efficiency and reduce manual operation with the help of automated equipment. Automated stacking usually uses equipment such as stackers, automated guided vehicles, and automatic control systems to achieve mechanized stacking operations and improve efficiency and accuracy.

Container depots are the transit points that connect sea and land transport. Yard management is an important part of terminal production, and reasonable arrangement of container space in the yard can not only improve the loading and unloading speed of the dock and reduce the turnover rateMoreover, it can also improve the utilization of the terminal yard and minimize the production cost of the terminal. The premise of optimal management of the yard is the reasonable entry of import and export containers, in the process of yard management and container loading and transportationIn order to meet the loading stability conditions, the heavier containers are required to be placed on the lighter top, and at the same time, in order to optimize the subsequent container picking operation, reduce the number of reloadingWhen requiring containers to enter the market, the tightness of the delivery date should be considered, that is, the order to which the goods belong has a late delivery date.

The application of laser distance sensors in container stacking problems is to measure the distance between the container and the container through laser technology, so as to provide real-time distance data to help operators or automated equipment in the stacking operation.

The application and advantages of laser distance sensors in container yard stacking problems include the following:

1. High-precision ranging: In container yards, the height of stacking is usually higher, so high-precision ranging technology is required to accurately measure the height of containers. Laser distance sensors can provide high-precision distance measurement to help operators or automation equipment accurately determine the stacking height of containers, avoid exceeding safety limits, and ensure the stability of operations.

2. Quick Response & Stability: The laser distance sensor has a fast response and is able to acquire distance data in a very short time and update it in real time. This allows the sensor to monitor changes in the position and height of containers in real time, detect stacking instability in time, and thus warn operators or automated systems to take measures to ensure the stability and safety of stacking.

3. Space utilization: Container yards often need to maximize the use of available space. Laser distance sensors can accurately measure the distance between containers, helping to optimize the stacking layout and ensure minimal spacing between containers, resulting in more efficient use of space.

4. Automation: In automated stacking systems, laser distance sensors play a key role. By providing real-time distance data, sensors help automated equipment, such as palletizing robots, accurately identify the position and height of containers for automated palletizing operations. This increases automation, reduces manual intervention, and increases operational efficiency.

5. High adaptability: The laser distance sensor is suitable for a variety of environments, whether indoor or outdoor, bright or dim, it can provide stable and reliable ranging data. This allows it to be reliably used in container yard stacking under different conditions.

6. Non-contact measurement: The laser distance sensor is a non-contact measurement technology that does not require the object to be in direct contact with the sensor, avoiding the risk of object damage or sensor contamination. This is especially important for stacking objects, as they are often heavy and valuable.

Siman Recommended Model:

The QG100 laser distance sensor is supported by the following technical support for this application

1. High ranging range: QG100 laser distance sensor can quickly and accurately carry out non-contact measurement, which can reach outdoor bright lightDistances of more than 100 meters (0.4-100m) are measured, covering the range of distances commonly found in container yards. This allows operators to obtain accurate stack height information without touching the container, improving the safety and efficiency of operations.

2. Suitable for different environments: The laser distance sensor can be widely used in indoor and outdoor environments, and has the ability to resist outdoor strong light. Whether it's in an enclosed yard environment or an outdoor yard exposed to sunlight, the sensor is able to measure distances consistently and accurately. It has an operating temperature range of -30°C to +60°C indoors and outdoors, and a minimum storage temperature of -40 to +70°C.

3. High-precision measurement: This laser distance sensor has excellent measurement accuracy, repeatability and accuracy±5cm。 During the stacking process at a container yard, accurate distance measurement is essential to ensure stacking stability. The sensor monitors the stacking height of containers in real-time and provides high-precision measurement data to help operators avoid stacking errors and improve operational efficiency and safety in the yard.

4. High response speed: This laser distance sensor has a fast response speed and is able to measure the change of container position during the stacking process in real time. With a measurement frequency of up to 1,000 times per second, the operator is able to adjust the stacking action in time by quickly capturing changes in the position of the case, improving the efficiency of the entire stacking process.

5. Universal Data Interface: This laser ranging sensor has a friendly and versatile data interface, including: RS485/RS232/4-20mA/TTL optional. This allows the sensor to be easily integrated with existing yard control systems, allowing operators to monitor and control the stacking process in real-time through the ranging data provided by the sensors, enabling smarter yard management.

6. High reliability and protection level: This laser distance sensor is industrial gradeIts black aluminium alloy housing provides a good degree of protection IP67, ensuring the stability and durability of the sensor in harsh environments. This protection allows the sensor to work reliably for a long time in the yard.

7. Compact size and easy integration: This laser distance sensor has a small size (63.4×60×35mm), which is convenient for easy integration into equipment such as stacking machinery. Its compact size allows the sensor to be easily installed on yard equipment without having much impact on the overall structure of the equipment.

8. Safety guarantee: The laser distance sensor belongs to the laser grade of a kind of eye-safe laser products, and there is no need to worry about safety issues when using it. Operators can confidently use the sensor for distance measurement without any harm to the safety of the user and others.

To sum up, the QG100 laser distance sensor has the advantages of long ranging, adaptation to a variety of environments, high-precision measurement, high response speed, universal data interface, high reliability and protection level, compact size and good safety guarantee in the stacking problem of container yard. By applying this laser distance sensor, operators can monitor and control the stacking process in real time, improving the efficiency and safety of yard management.

Business Manager: Manager Jiang

Tel:13391208082

E-mail:13391208082@163.com

Business Manager: Manager Li

Tel:18737118612

E-mail:18737118612@163.com

Business Manager: Manager Lv

Tel:15238312802

E-mail:15238312802@163.com

Business Manager: Manager Wang

Tel:15238360758

E-mail:15238360758@163.com

Copyright © 2024 Siman Sensor Technology Co., Ltd. 豫ICP备2024098333号