Recently, a domestic high-tech company in the field of wind power tested the laser clearance radar developed by our company. After the actual test, the problem of blade deformation monitoring is perfectly solved. The two sides reached a long-term cooperation willingness.

Test site 1

Test site 2

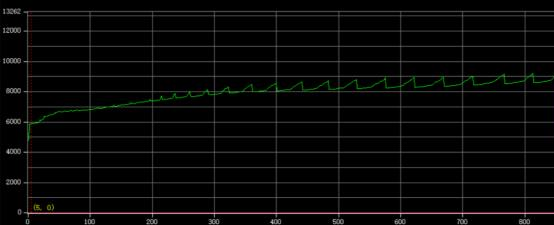

Data images

Based on the principle of ranging, the JK-A1 laser clearance radar developed by our company judges the clearance distance between the blades and the tower in wind power generation, so as to prevent the risk of sweeping the tower caused by the wind turbine blades due to the complex geographical environment of the wind turbine location, the complex wind conditions or the complex meteorological conditions such as cold snaps and typhoons, so as to ensure that the wind power generation equipment is always in a qualified working state.

JK-A1 laser clearance radar uses high-speed lidar, with a response time of less than 0.01ms, and can detect various types of blades (blade length covers 150meters), the effective detection rate of leaves ≥99.99%. The JK-A1 integrates an infrared camera inside to achieve zero-error installation for visualization. It has the ability to work in all weather and all environments, anti-rain and fog, anti-electromagnetic interference, and anti--40°C low temperature.

JK-A1 laser clearance radar is a kind of lidar that monitors the clearance distance of the blade tip in real time, and accurately judges the clearance distance between the blade and the tower in wind power generation through the detection of the blade clearance distance. When the blade clearance value is close to the specified minimum clearance value, the main control of the wind turbine unit can immediately take protective measures, such as deceleration, propeller retraction, etc. The application of clearance radar in existing units can play a role in preventing tower sweeping, lifting the power limitation of dangerous units and increasing power generation, and the application of clearance radar in future units can play a role in reducing the cost of blades and reducing the design pressure of units.

Business Manager: Manager Jiang

Tel:13391208082

E-mail:13391208082@163.com

Business Manager: Manager Li

Tel:18737118612

E-mail:18737118612@163.com

Business Manager: Manager Lv

Tel:15238312802

E-mail:15238312802@163.com

Business Manager: Manager Wang

Tel:15238360758

E-mail:15238360758@163.com

Copyright © 2024 Siman Sensor Technology Co., Ltd. 豫ICP备2024098333号